New Material Advancements Engineered from Beetle Wings

Many modern innovations can be traced to adaptations of the natural world around us, but applying the principles found in nature to real-world implementations is not exactly apples-to-apples. Velcro comes from a plant burr, wind turbines are based off a whale fin and road reflectors that help guide us at night can be traced to the reflective properties of a cat’s eye.

Recently, engineers turned their attention to the unique bell-shaped wing structure of a sun beetle (Pachnoda marginata). Because of its two distinguishable layers—a bell-shaped upper layer and a nearly straight lower layer—the wing is stiff in tension and upward bending, but flexible in compression and downward bending. (Figure 1)

Figure 1: Sun beetle (Pachnoda marginata)

This discovery on how the beetle’s hindwing membrane changes shape in flight has enabled the London South Bank University School of Engineering to develop a one-way hinge design with biomimetic applicability over a considerable size range. Biomimetic materials are synthetic materials that replicate natural biological objects. And because they are man-made, these material designs need testing.

A New Hinge Design Takes Flight

The insect-inspired hinge concept is being explored across many industries, including a modular design that can easily be assembled and disassemble, as a design for adaptive airless tires and as metamaterials with zero Poisson’s ratio, where the compressive behavior of the material is controlled using joints, since the material does not transversally deform in response to an axial strain.

Hamed Rajabi, Lecturer in Mechanical Engineering & Design at the university’s School of Engineering, explained, “By systematically varying its design parameters in a computational model, we showed that the properties of the double-layer membrane hinge can be tuned over a wide range. This enabled us to develop a broad design space, which we later used for model selection.”

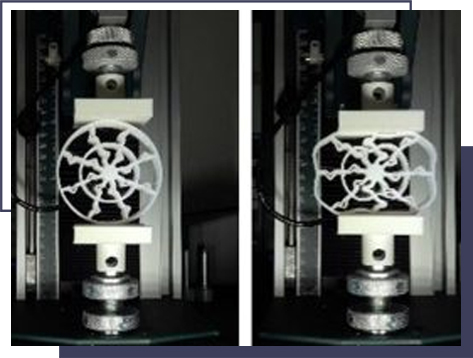

“We used selected models in three distinct applications, which proved that the double-layer hinge represents a simple, yet effective, design strategy for controlling the mechanical response of structures using a single material and with no extra mass.” (Figure 2)

Figure 2: Model-based designs showed that the double-layer membrane hinge properties could be tuned over a wide range for application development across a broad design space.

Engineering New Materials

To ensure these various model-based scenarios had real-world applicability, Rajabi employed a universal testing machine (UTM) equipped with a 500N loadcell from Tinius Olsen to not only performed the required tension and compression testing, but also to be used in combination with the custom setups developed by Hamed and his team.

Available with a variety of loadcells at differing capacities to give precise applied load measurements, the robust 1ST is designed for tension, compression, flexure and shear strength testing on materials and assemblies. It can handle scenarios from the smallest test specimen to ones that go to full machine capacity.

“The support from Tinius Olsen with this project was incredible. The comprehensive help and support provided with the selection of the correct testing machine, load cell and accessories was invaluable. Their support staff were always available to answer any questions we had and the full day instruction on the 1ST and Horizon software was especially helpful, as well as developing all the testing protocols we required. We certainly wouldn’t have achieved what we have with this study without the company’s input,” noted Rajabi.

For the modular designs, the double-layer membrane hinge was tested in three-point bending and subjected to a displacement of 10 mm at a constant velocity of 1 mm/sec in two opposite directions.

Both the airless tire and metamaterial were tested in compression, with the airless tire design subjected to a displacement of 20 mm at a constant velocity of 1 mm/sec between two flat plates, while the metamaterial subjected to a maximum force of ~500N at an increasing displacement of 1 mm/sec between two flat plates. (Figure 3)

Figure 3: Material testing of the designs proved critical to ensure the safety, reliability and validity of the engineered concepts.

Proper Testing Scenarios

Compression testing measures fundamental variables, including stress, strain and deformation as a material experiences a compressive load, to help determine the behavior or response of that material. The goal is to determine whether a material is suitable for specific applications or if it will fail under specified stresses.

Tensile strength is the stress at which a material breaks or permanently deforms and is common when testing materials used in structural applications or in mechanical designs. Typically, a clamped specimen is subjected to a constant rate of tensile loading such that it stretches and ultimately breaks.

When engineering new materials that will be brought to market, these are critical parameters to ensure both reliability and safety as well as improve cost-efficiencies. Knowing the expected outcome of an initial new concept will help engineers move farther into product development and technological innovation.

Rajabi explains, “This biological one-way hinge offers biometric inspiration for the design and development of engineering structures that exhibit asymmetric responses to equal forces applied in different directions. This is particularly interesting because the double-layer membrane offers a simple, inexpensive way of making a one-way hinge without increasing the mass.”

But can this inspirational concept be realized in the real world? The data and insights gained using a Tinius Olsen material testing system helps engineers understand not only the limitation, but the possibilities of newly engineered materials. The results enable even further applications of new innovations, like in the case of the hinged beetle wing.

“In this particular instance, the hinge is of a double membrane type, which is dependent on reversible thin-plate buckling. From real-scale computational simulations and upscaled physical modelling, it was confirmed this double-layer membrane can act as a one-way hinge.”

Materials Testing Strengthens Innovation

Our modern world runs on the engineered technologies made possible through innovation, but it is materials testing that has long been relied upon to bring these concepts to fruition. Realizing design advancements beyond hypothesis requires solid analytics and proven testing methods that will ensure product reliability, consumer safety and long-term yield.