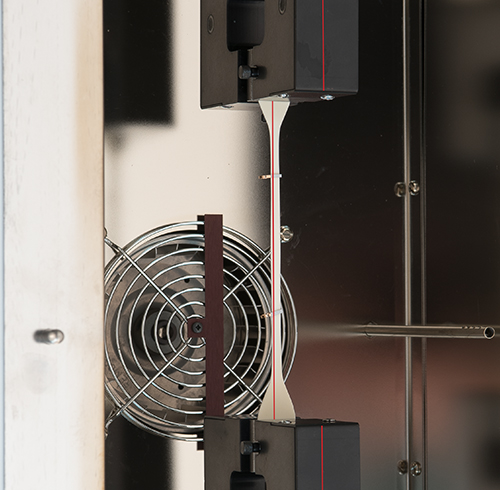

Tinius Olsen model 600LS non-contacting extensometer is designed to measure the extension of medium to high elongation materials, typically elastomers. Since there is no contact of this extensometer with the sample, the 600LS is ideal for also measuring the elongation of fragile samples where such contact could induce a premature sample break.

The model 600LS uses a low power laser diode with precision optical components and a dedicated 32 bit processor. The laser projects a visible red scanning beam that is directed at two reflective targets attached to the specimen. An additional benefit of using laser technology is its ability to scan the test specimen through the glass viewing window of an environmental test

chamber. Elongation characteristics can then be evaluated from –70° C to 300° C.

Measuring Extension

Marking the test specimen with gauge marks is easy using two pieces of self-adhesive reflective tape (supplied) no less than 2mm in width. Any gauge length size maybe defined, minimum 10mm, this is accurately measured and automatically recorded by the extensometer at the start of the test. Once the test starts the instantaneous strain is automatically captured using the scanning laser at a scan rate of 660 times per second (660 Hz). If the scanning beam is interrupted for any reason, strain measurements are automatically corrected and continued when the laser beam is clear and picks up the gauge mark targets.

Specifications

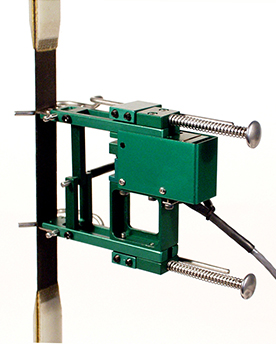

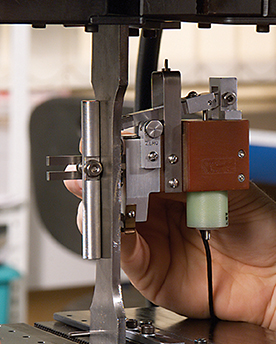

Strain Gage Type Extensometer

Strain Gage Type Extensometer

VectorExtensometer U200

VectorExtensometer U200

VectorExtensometer B80

VectorExtensometer B80

100R Extensometer

100R Extensometer

100S Extensometer

100S Extensometer

500LC Laser Extensometer

500LC Laser Extensometer

Automatic Extensometer

Automatic Extensometer

LVDT Type Extensometer

LVDT Type Extensometer