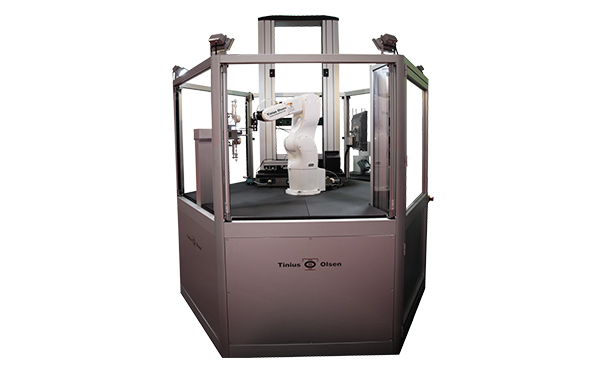

Tinius Olsen

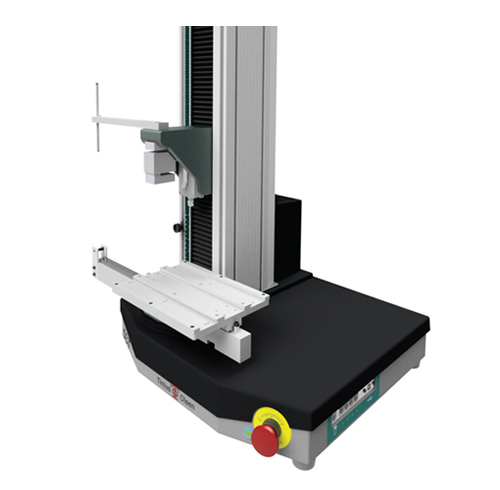

Automated System Cell

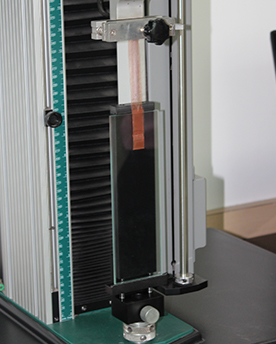

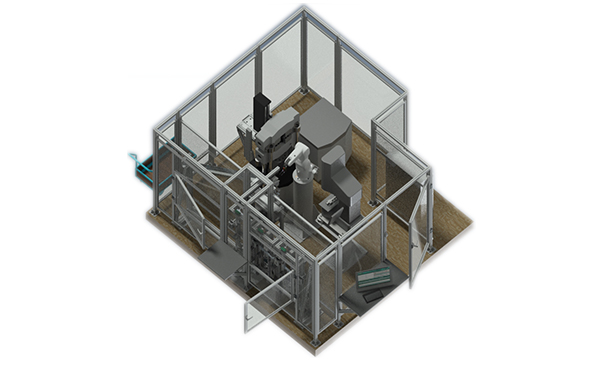

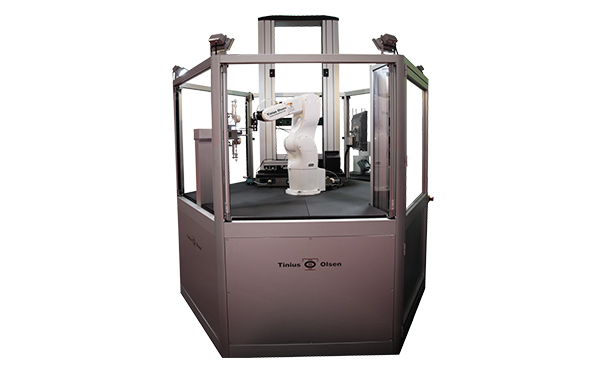

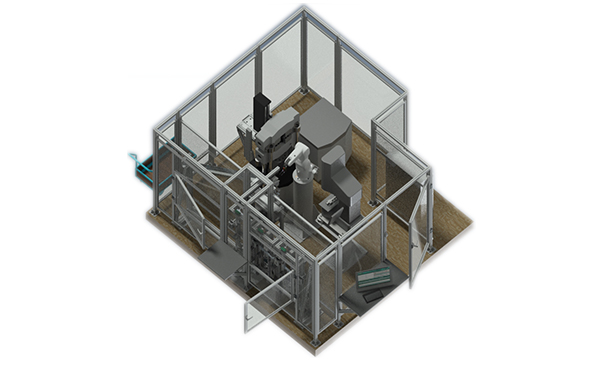

The key to the entire automated robotic testing system is that it can run without operator involvement. While this by itself has numerous advantages, it presents a possibility of a hazard to unfamiliar bystanders if the robot moves. To prevent any damage to operators and onlookers the entire testing system can be surrounded by polycarbonate safety shielding, with interlocked access doors and specimen loading doors to prevent any unauthorised access.

Automated Systems are built to accommodate your testing system be it housing a single machine or multiple machines, tensile, compression, flexural, impact, hardness, melt flow. The cell is impact resistant and transparent; it is interlocked with user and service password modes of entry.

The cell housing the automation system is configured with four specific objectives and capabilities;

● FOOTPRINT Optimize the footprint and envelope of the automation cell in support of productivity.

● SAFETY Transparent impact resistant panels give the user a clear a view of the system while providing protection from moving parts. Optional user recognition

for interlocked cell access for users and/or service personnel.

● ACCESS Light curtains in the cell panels allow people to operate safely while near the robotics.

● FLEXIBILITY The system is an investment in performance for many years, therefore the cell design and construction supports future repositioning if required.

-

Download User Instruction Manual

Please Fill the Fields to download pdf

-

Download Brochure

Please Fill the Fields to download pdf

- Request a Quote

Request a Proposal

Similar Accessories

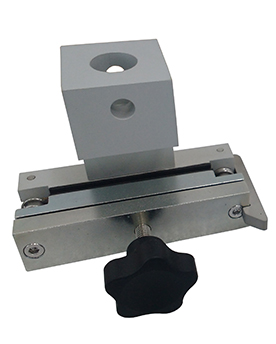

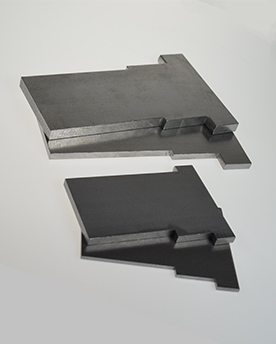

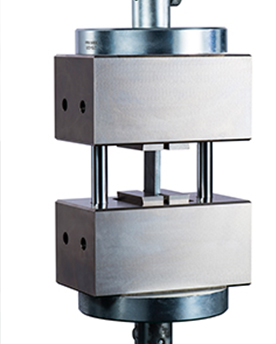

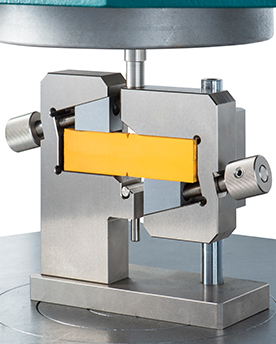

Shear Loading Compression Fixture

Shear Loading Compression Fixture

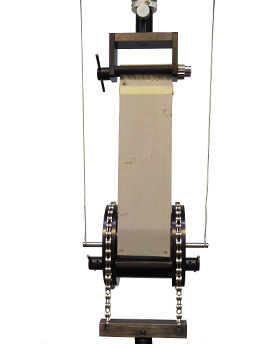

Specimen Identification Station

Specimen Identification Station

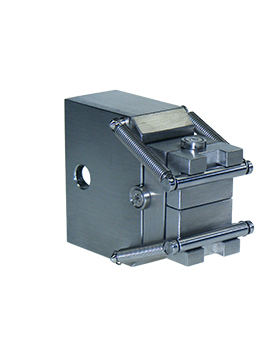

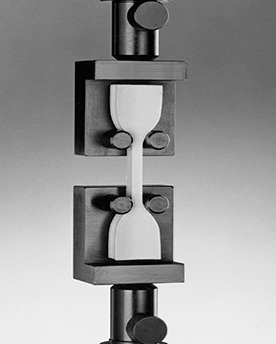

Combined Loading Compression Fixture

Combined Loading Compression Fixture

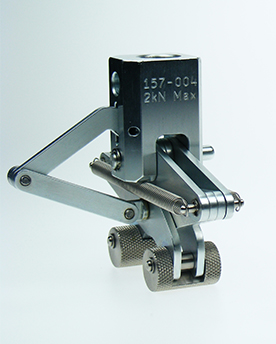

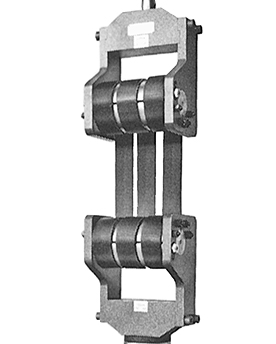

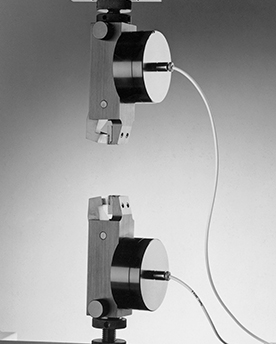

HT53 Miniature Knurled Roller Grips

HT53 Miniature Knurled Roller Grips

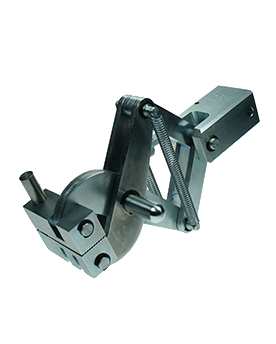

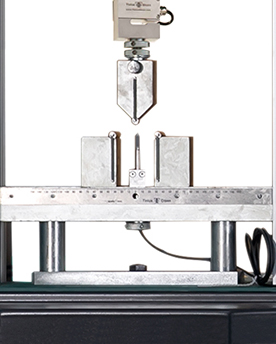

V-notched Shear Compression Fixture

V-notched Shear Compression Fixture

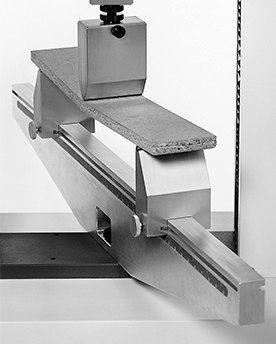

HF74 3-Point Wide Variable Flexural

HF74 3-Point Wide Variable Flexural

Compression Cage for Environmental Chamber

Compression Cage for Environmental Chamber

Flex cage for Environmental Chamber

Flex cage for Environmental Chamber

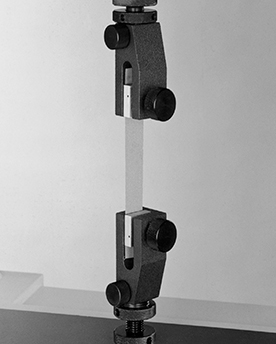

122-007 Side operating Pneumatic Grip, 5kN

122-007 Side operating Pneumatic Grip, 5kN

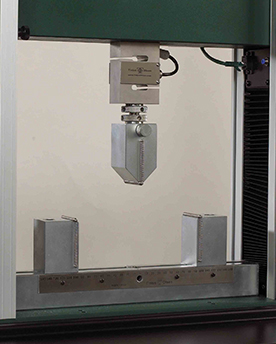

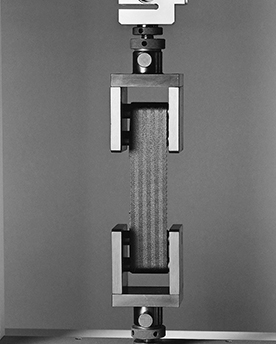

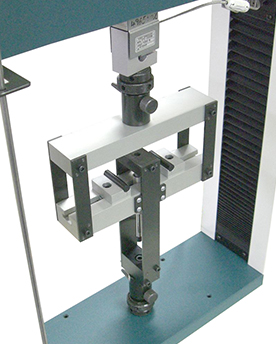

330-012 3-Point Flex Test with LVDT

330-012 3-Point Flex Test with LVDT

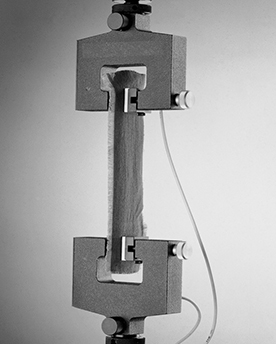

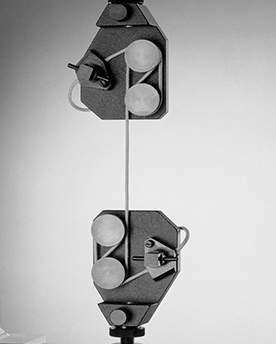

HT58 Lightweight Pneumatic Grips

HT58 Lightweight Pneumatic Grips

Double Shear Bearing Strength Test - Procedure A

Double Shear Bearing Strength Test - Procedure A

Short Beam 3-point Flexural Fixture

Short Beam 3-point Flexural Fixture

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Bearing Strength Test - Procedure C

Single Shear Bearing Strength Test - Procedure C