Tinius Olsen

HMC 3.0

This interface can be used on both the ST and SL series of testers. It features an Android-based operating platform and can be used to control the machine by itself or in conjunction with Tinius Olsen’s Horizon software.

Features & Benefits

- Bluetooth-enabled handheld interface allows maximum flexibility when paired to a testing machine.

- 10.1” Display with 1920 X 1200 Resolution

- Typical battery life is approximately 20+ hours of continuous use.

- Three-channel display of test machine channels.

- Selectable multi-unit display of channel values.

- Safe operating radius of a maximum 10m. If range is exceeded for testing, the machine will operate in ‘safe’ mode.

- Controls machine movement during test set-up and initiates a test directly from the application.

- Instantaneous display of machine status and channel values.

- If running without the Horizon software, testing procedure can be set up using up to five simple steps. These steps include move, hold and cycle routines.

- Test results can be sent directly to a Wi-Fi enabled printer or connected to a PC via USB-A/USB-C connection.

- 13MP AF back and 8MP front camera can be used to take pictures of specimens, tests and configurations as witness to each test.

- Interface has Full HD 1080p video at 30fps capability to record test procedure.

- Stylus is included.

Specifications

- Compatible with TO ST and SL series frames and most other VMC controlled machines

- Colour: Yes

- Operating system: Android 12

- CPU: Qualcomm SM7325

- Processor: 2.4Ghz/1.8Ghz, Octa-core

- Memory (RAM): 4GB

- Memory (Internal/External): 64GB 9/MicroSD (upto 1TB)

- Display/Display type: Screen size 10.1’’/TFT

- Display resolution: WXGA (1920 x 1200)

- Brightness: 550 nits

- Camera (back/front): 13.0MP Auto focus with LED flash/8.0MP

- Video recording resolution: FHD (1920 x 1200) @ 360fps

- Video playing resolution: FHD (1920 x 1200) @ 360fps

- USB port: Type C USB 3.2/ Fast Charging

- Battery capacity: 7,600 mAh, user-replaceable battery

- Battery life: Up to 20+ hrs

- WiFi: Wi-Fi 6 Supported

- Stylus: Integrated S pen (water and dust resistant, IP68 rated)

- Charging time: 160 minutes

- Dimensions: 285.75 x 190.5 x 31.75mm

- Weight: 674gm

- Download Brochure

Please Fill the Fields to download pdf

- Mail us

Request a Proposal

Similar Accessories

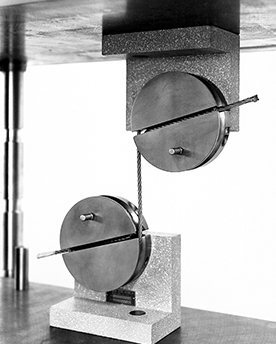

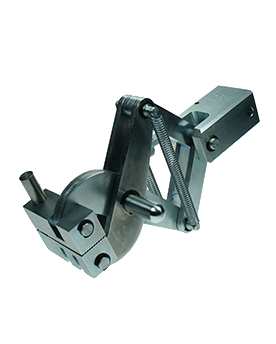

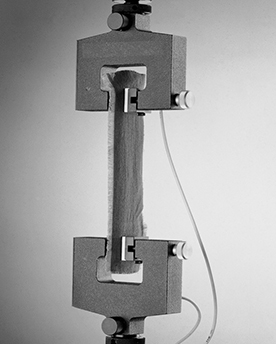

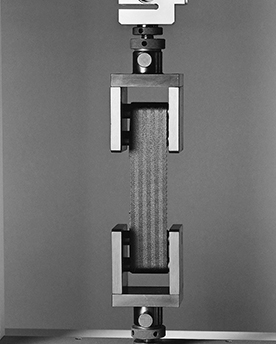

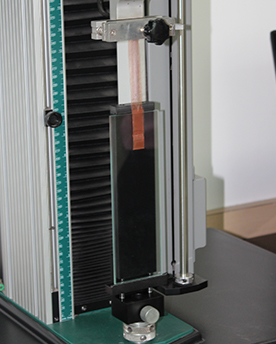

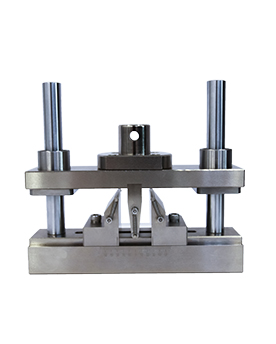

HT53 Miniature Knurled Roller Grips

HT53 Miniature Knurled Roller Grips

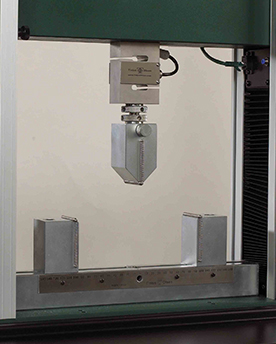

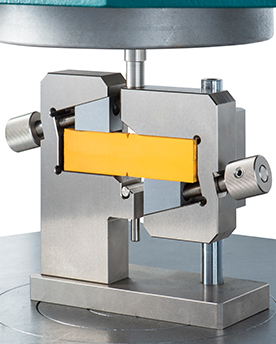

V-notched Shear Compression Fixture

V-notched Shear Compression Fixture

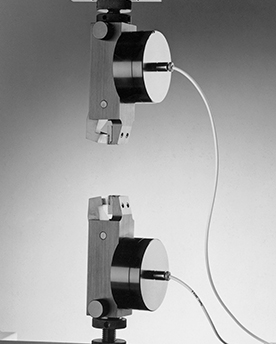

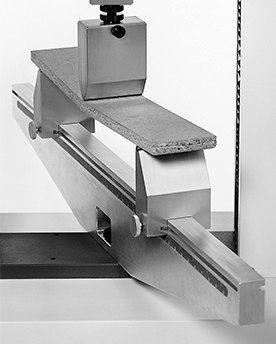

HF74 3-Point Wide Variable Flexural

HF74 3-Point Wide Variable Flexural

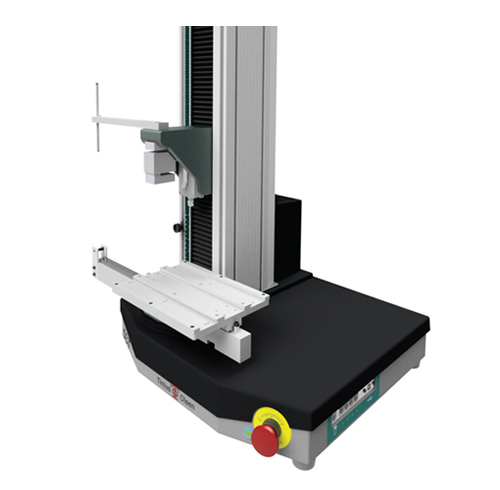

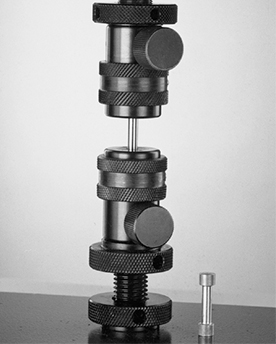

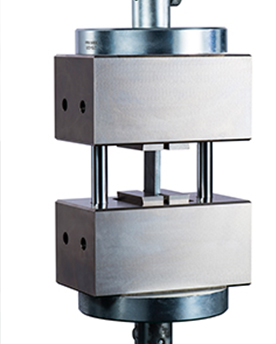

Compression Cage for Environmental Chamber

Compression Cage for Environmental Chamber

Flex cage for Environmental Chamber

Flex cage for Environmental Chamber

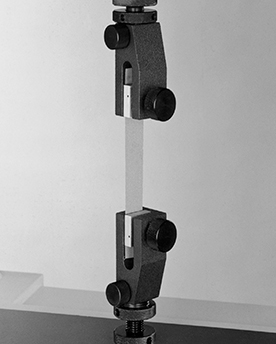

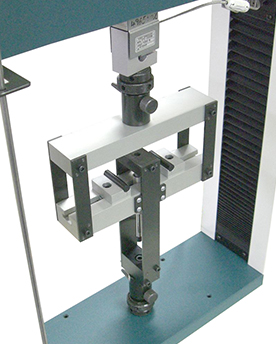

330-012 3-Point Flex Test with LVDT

330-012 3-Point Flex Test with LVDT

Short Beam 3-point Flexural Fixture

Short Beam 3-point Flexural Fixture

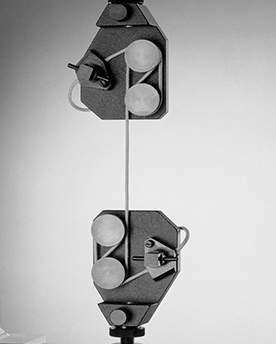

HT58 Lightweight Pneumatic Grips

HT58 Lightweight Pneumatic Grips

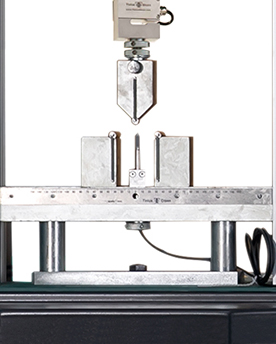

Double Shear Bearing Strength Test - Procedure A

Double Shear Bearing Strength Test - Procedure A

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Bearing Strength Test - Procedure C

Single Shear Bearing Strength Test - Procedure C

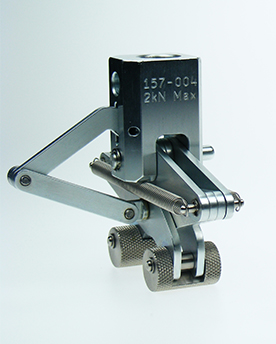

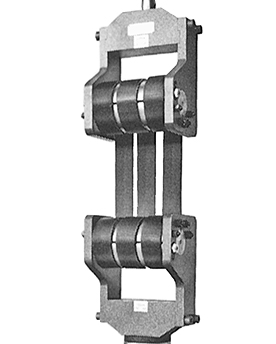

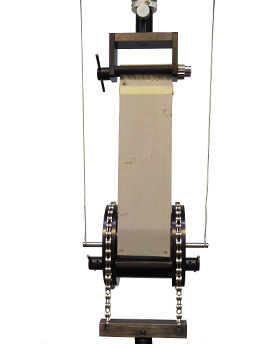

Compression Anti-Buckling Fixture

Compression Anti-Buckling Fixture

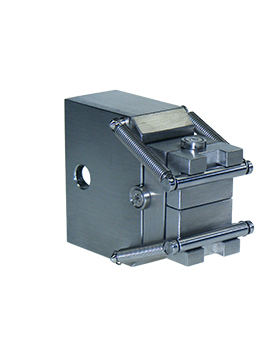

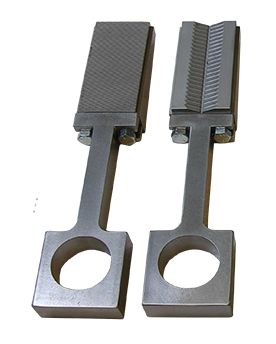

Shear Loading Compression Fixture

Shear Loading Compression Fixture

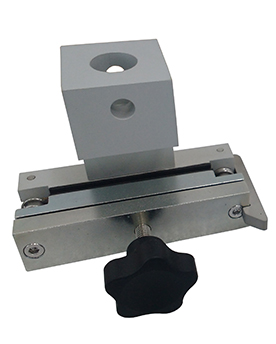

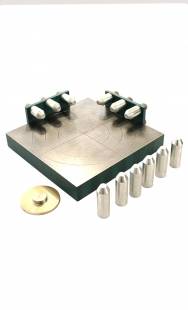

Specimen Identification Station

Specimen Identification Station