Tinius Olsen

Horizon Software

Using Horizon will make easy work of materials testing, whether it’s designed for the demanding rigors of R&D or the charting and analysis functions of QC testing.

Features & Benefits

- Advanced machine segment control

- Customizable report layout

- Data archiving and backup

- Data exporting (results/limits/statistics/points)

- Data importing (result entries/limits)

- Data stored with SQL Server Express

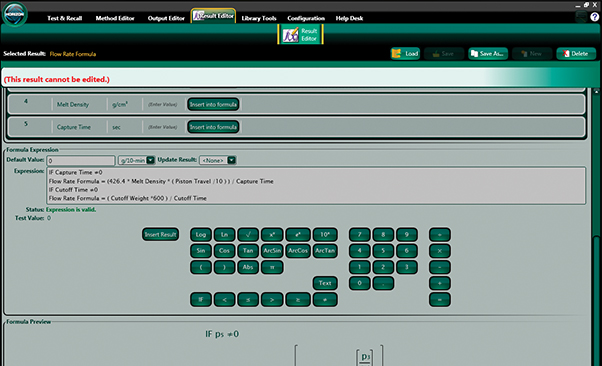

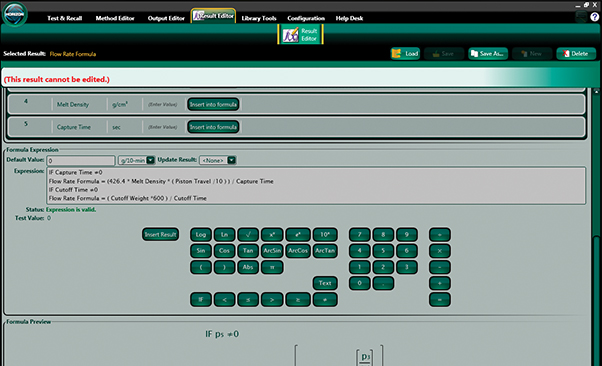

- Formula beneration

- Library of pre-defined testing programs

- Method/output editor

- Multiple graphs/reports for output

- Multiple machines controlled by one Horizon

- Multiple users

- Networking databases

- Report consolidation

- RS232 device communication

- Security lockout capability

- Touchscreen capability

- Video extensometer capability

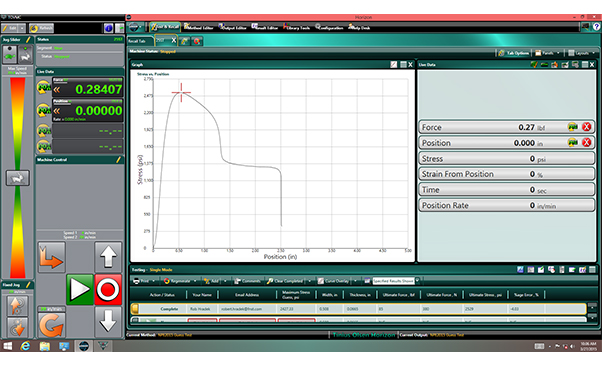

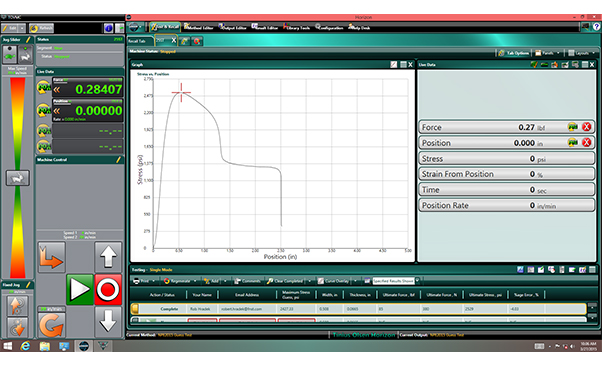

Test & Recall

Custom Results

Help Desk

Webcam Functionality

- Download Brochure

Please Fill the Fields to download pdf

- Mail us

Request a Proposal

Similar Accessories

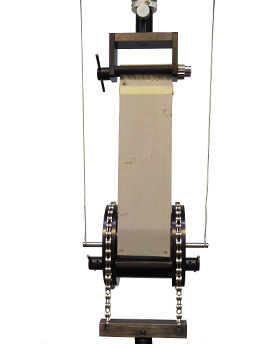

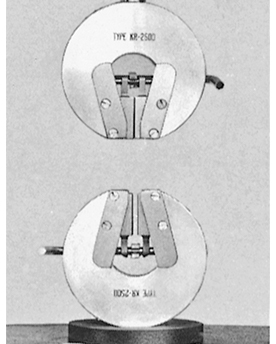

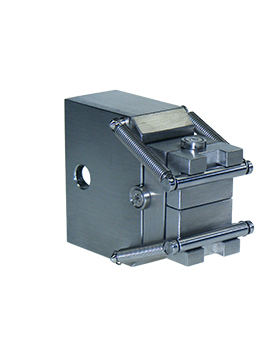

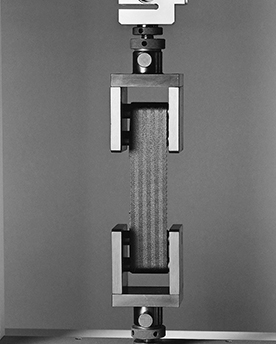

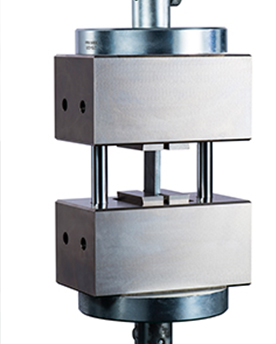

Compression Anti-Buckling Fixture

Compression Anti-Buckling Fixture

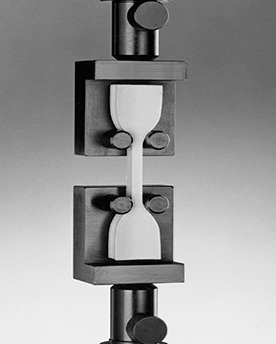

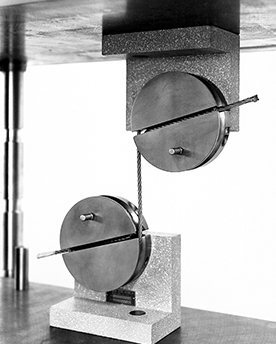

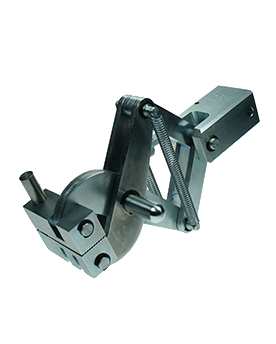

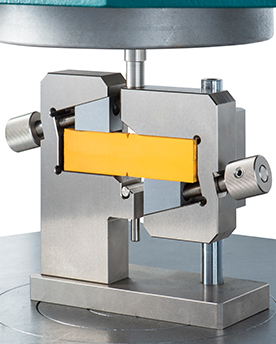

Shear Loading Compression Fixture

Shear Loading Compression Fixture

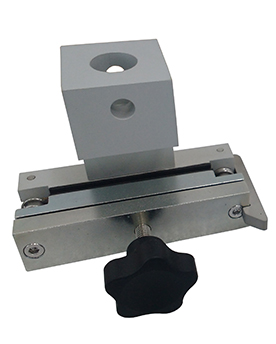

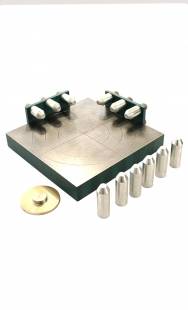

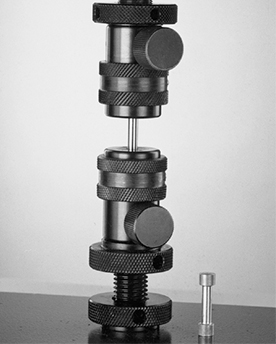

Specimen Identification Station

Specimen Identification Station

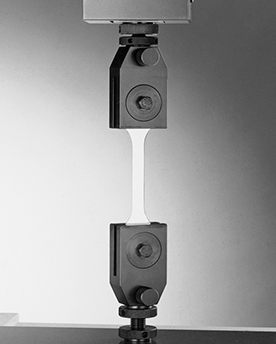

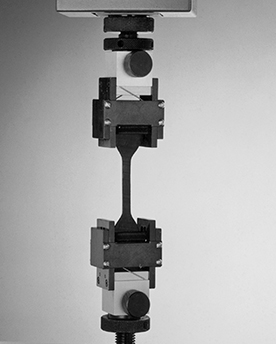

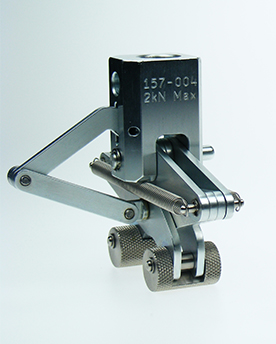

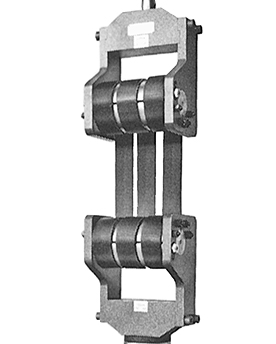

Combined Loading Compression Fixture

Combined Loading Compression Fixture

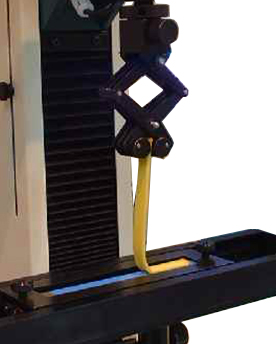

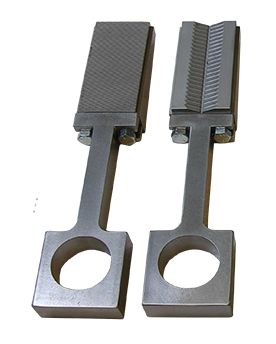

HT53 Miniature Knurled Roller Grips

HT53 Miniature Knurled Roller Grips

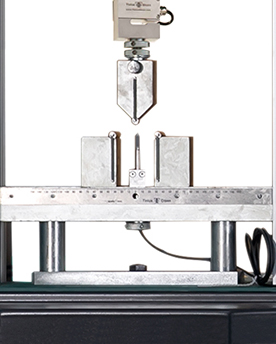

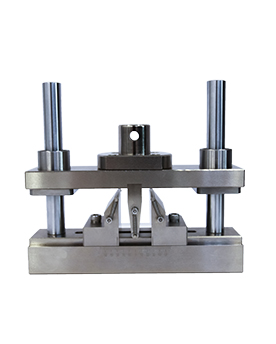

V-notched Shear Compression Fixture

V-notched Shear Compression Fixture

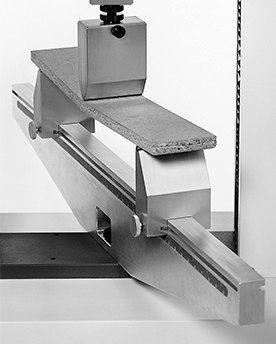

HF74 3-Point Wide Variable Flexural

HF74 3-Point Wide Variable Flexural

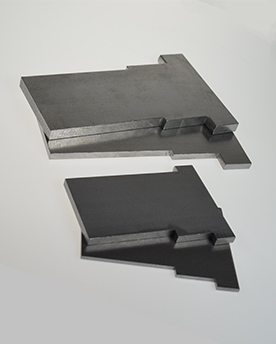

Compression Cage for Environmental Chamber

Compression Cage for Environmental Chamber

Flex cage for Environmental Chamber

Flex cage for Environmental Chamber

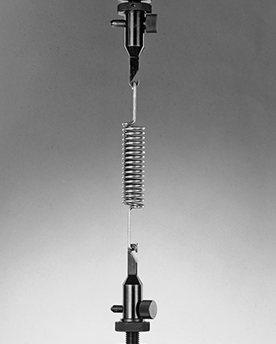

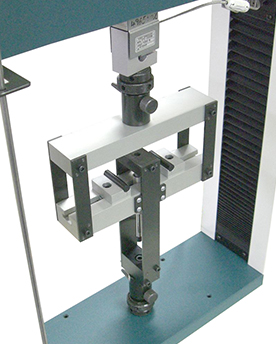

330-012 3-Point Flex Test with LVDT

330-012 3-Point Flex Test with LVDT

Short Beam 3-point Flexural Fixture

Short Beam 3-point Flexural Fixture

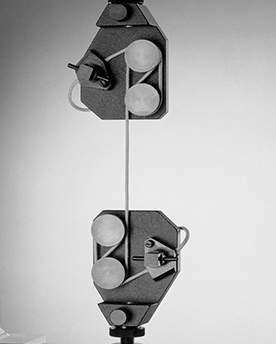

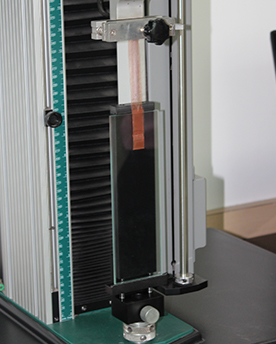

HT58 Lightweight Pneumatic Grips

HT58 Lightweight Pneumatic Grips

Double Shear Bearing Strength Test - Procedure A

Double Shear Bearing Strength Test - Procedure A

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Open Hole Bearing Test - Procedure B