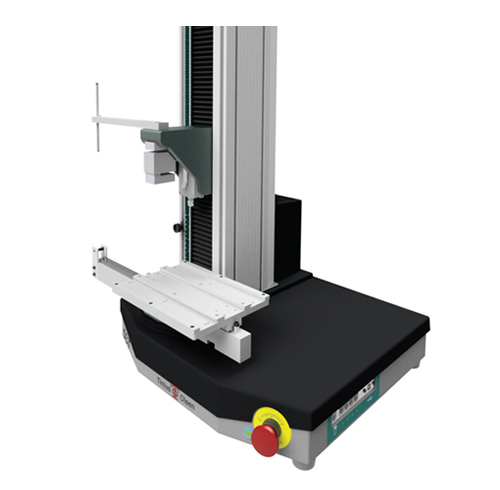

Tinius Olsen

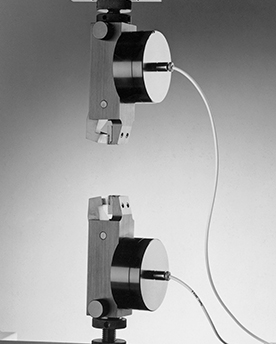

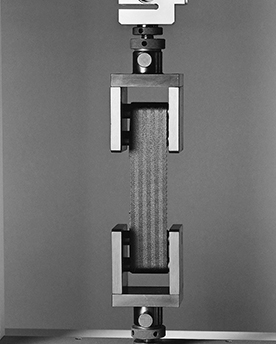

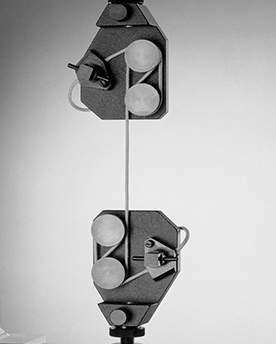

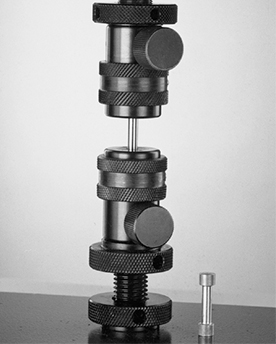

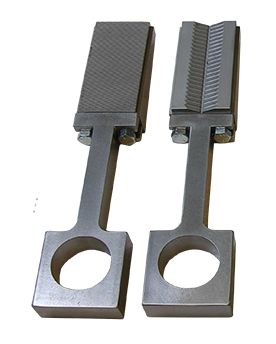

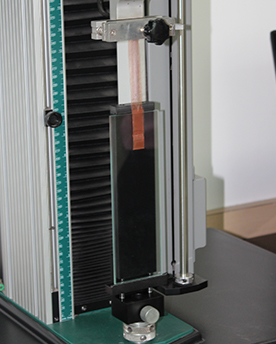

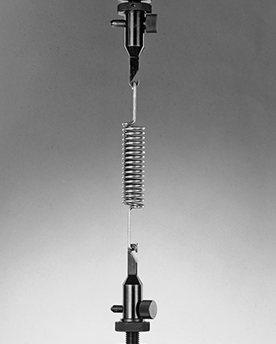

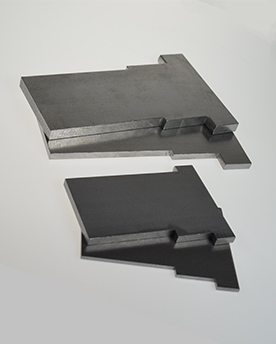

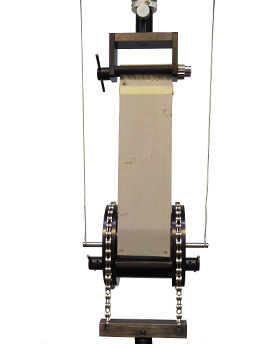

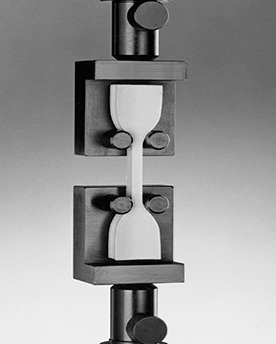

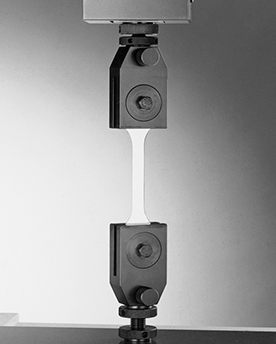

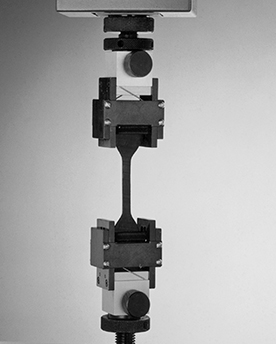

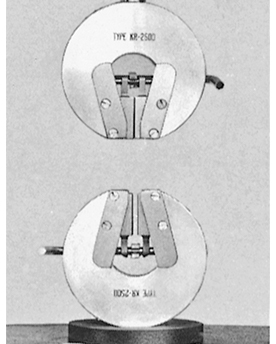

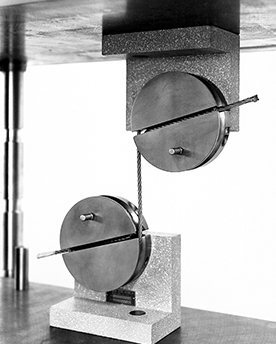

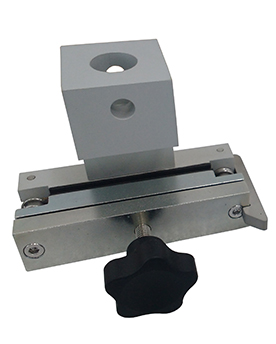

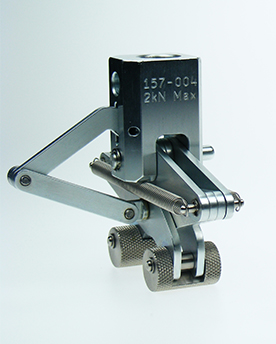

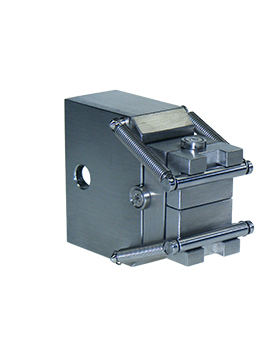

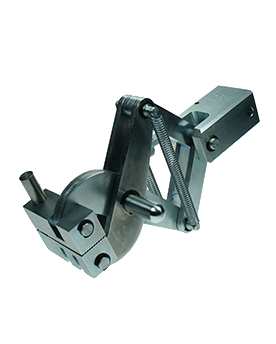

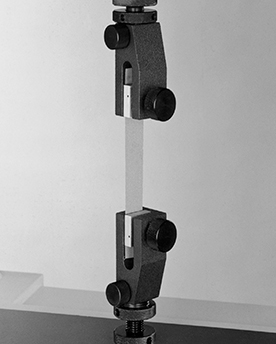

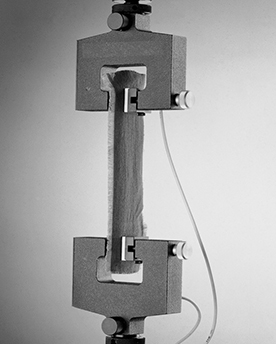

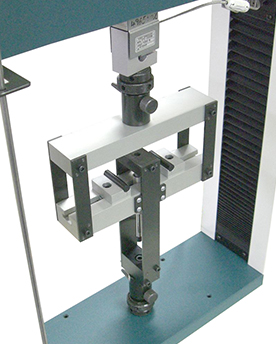

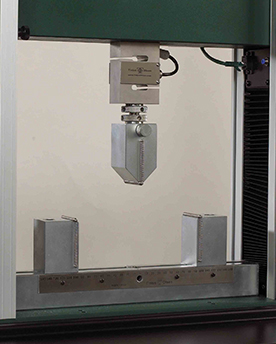

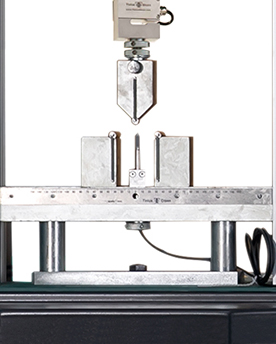

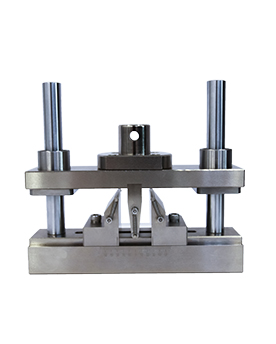

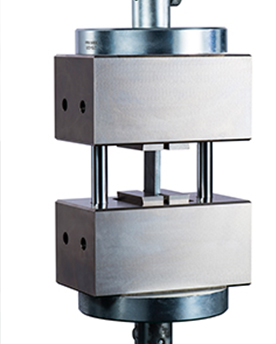

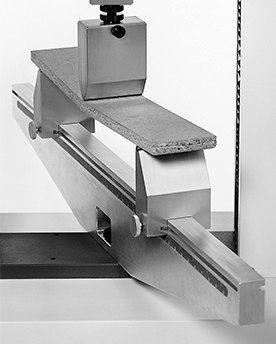

HW21 Wedge Grips

Specifications

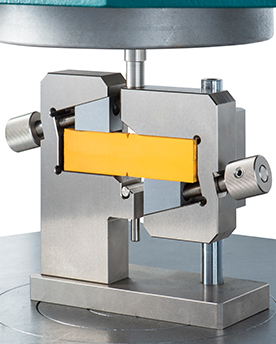

V profile jaw face options

Applications

Suitable for gripping high strength rigid material in parallel or dumbbell form. Ideally the overall sample length should be greater than 150mm (6in).

-

Download User Instruction Manual

Please Fill the Fields to download pdf

-

Download Brochure

Please Fill the Fields to download pdf

- Request a Quote

Request a Proposal

Similar Accessories

122-007 Side operating Pneumatic Grip, 5kN

122-007 Side operating Pneumatic Grip, 5kN

330-012 3-Point Flex Test with LVDT

330-012 3-Point Flex Test with LVDT

HT58 Lightweight Pneumatic Grips

HT58 Lightweight Pneumatic Grips

Double Shear Bearing Strength Test - Procedure A

Double Shear Bearing Strength Test - Procedure A

Short Beam 3-point Flexural Fixture

Short Beam 3-point Flexural Fixture

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Bearing Strength Test - Procedure C

Single Shear Bearing Strength Test - Procedure C

Compression Anti-Buckling Fixture

Compression Anti-Buckling Fixture

Shear Loading Compression Fixture

Shear Loading Compression Fixture

Specimen Identification Station

Specimen Identification Station

Combined Loading Compression Fixture

Combined Loading Compression Fixture

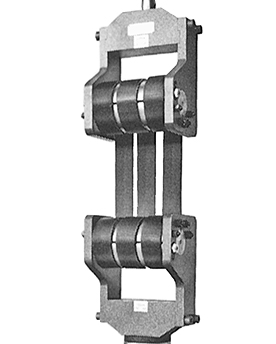

HT53 Miniature Knurled Roller Grips

HT53 Miniature Knurled Roller Grips

V-notched Shear Compression Fixture

V-notched Shear Compression Fixture

HF74 3-Point Wide Variable Flexural

HF74 3-Point Wide Variable Flexural

Compression Cage for Environmental Chamber

Compression Cage for Environmental Chamber