Tinius Olsen

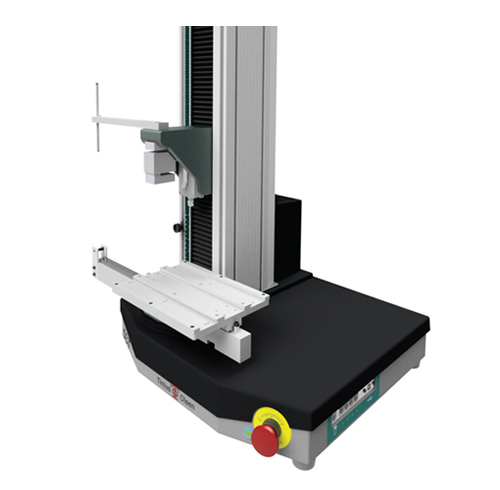

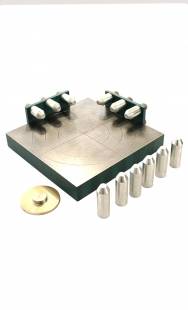

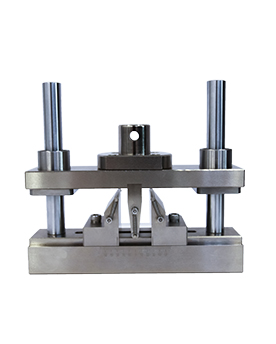

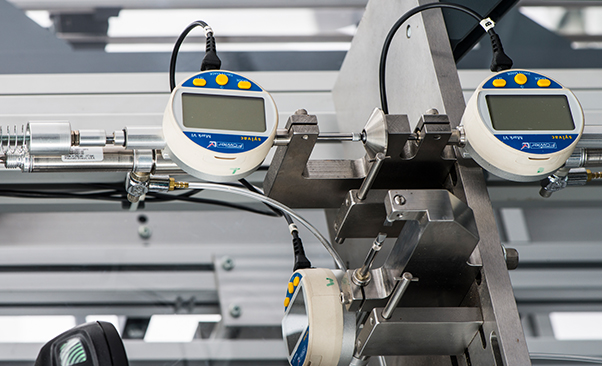

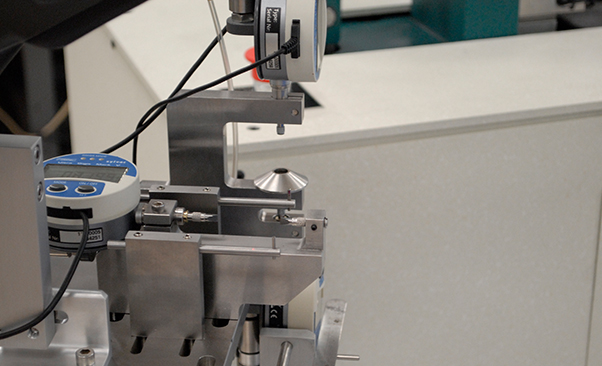

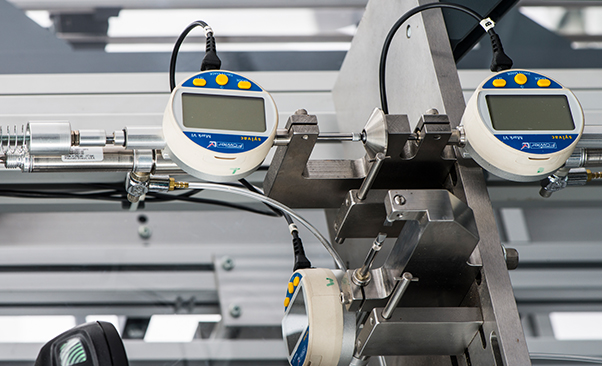

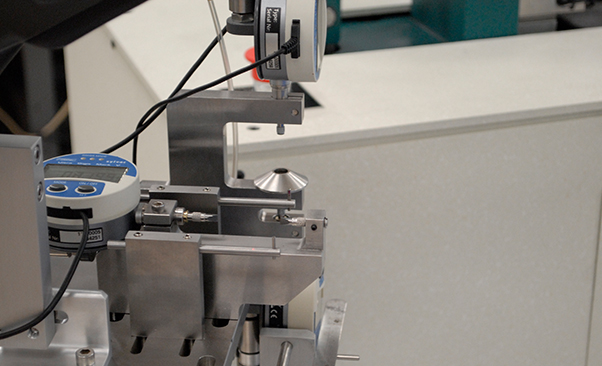

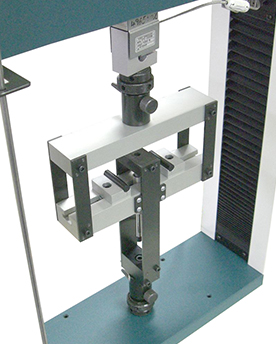

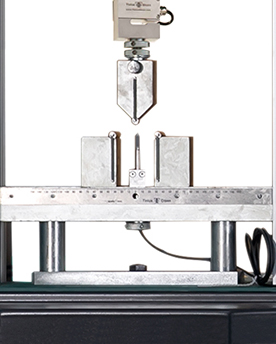

Specimen Measurement Station

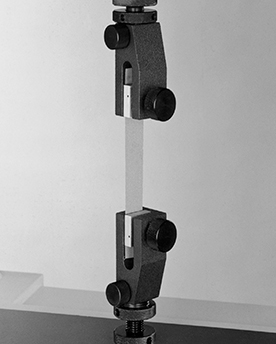

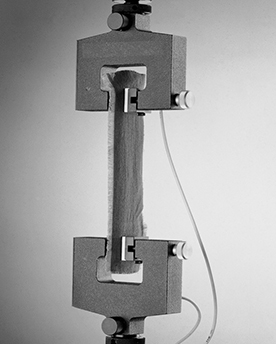

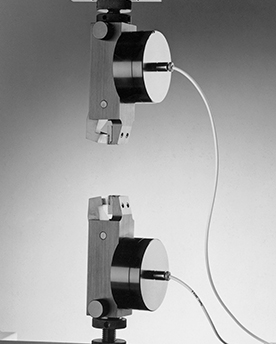

While the barcode information is being read and stored, the specimen width and thickness is measured in the reduced section of the specimen. The pneumatic arms on the width and thickness gauges are activated and the measurements recorded. Once recorded, the robot lifts and moves the specimen and the width and thickness measured for a second time. This is repeated a third time and the minimum values are logged into the computer.

- Download Brochure

Please Fill the Fields to download pdf

- Mail us

Request a Proposal

Similar Accessories

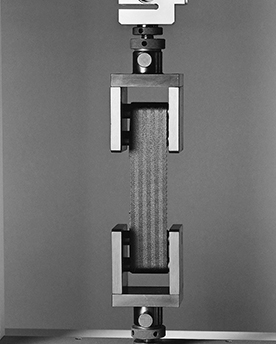

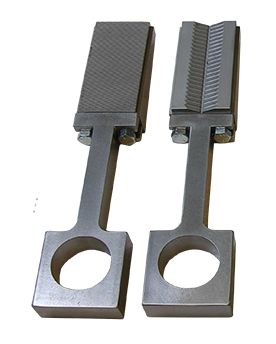

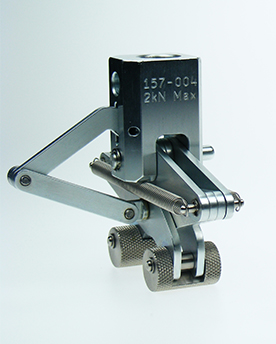

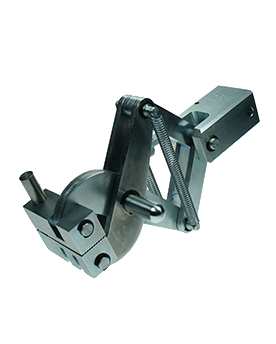

HT58 Lightweight Pneumatic Grips

HT58 Lightweight Pneumatic Grips

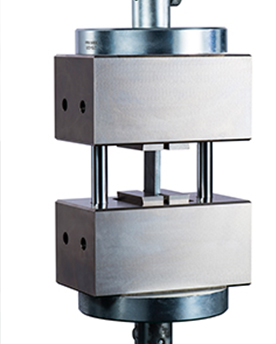

Double Shear Bearing Strength Test - Procedure A

Double Shear Bearing Strength Test - Procedure A

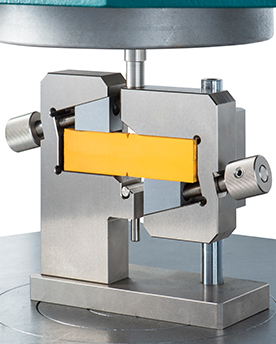

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Open Hole Bearing Test - Procedure B

Single Shear Bearing Strength Test - Procedure C

Single Shear Bearing Strength Test - Procedure C

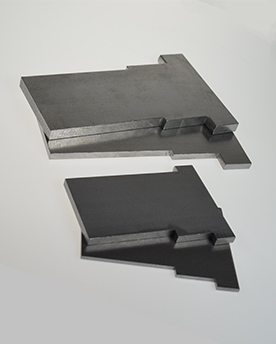

Compression Anti-Buckling Fixture

Compression Anti-Buckling Fixture

Shear Loading Compression Fixture

Shear Loading Compression Fixture

Specimen Identification Station

Specimen Identification Station

Combined Loading Compression Fixture

Combined Loading Compression Fixture

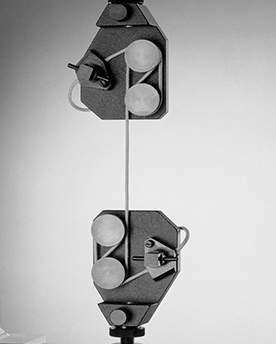

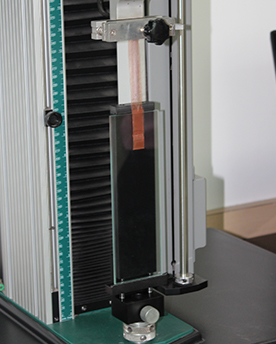

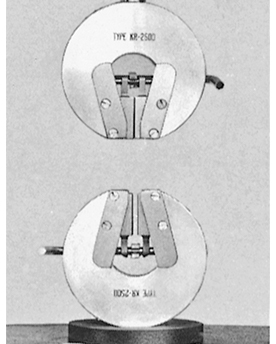

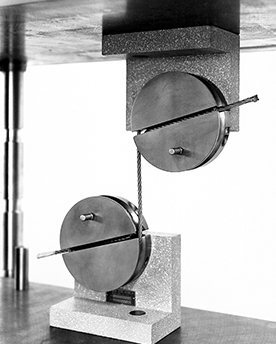

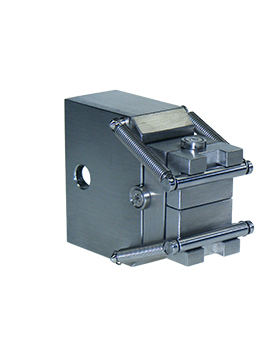

HT53 Miniature Knurled Roller Grips

HT53 Miniature Knurled Roller Grips

V-notched Shear Compression Fixture

V-notched Shear Compression Fixture

HF74 3-Point Wide Variable Flexural

HF74 3-Point Wide Variable Flexural

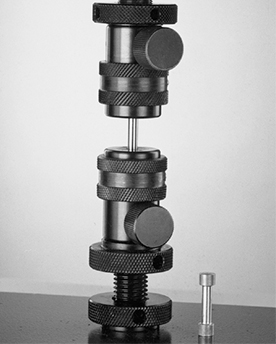

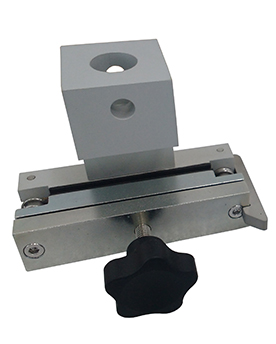

Compression Cage for Environmental Chamber

Compression Cage for Environmental Chamber

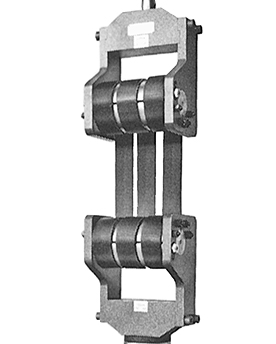

Flex cage for Environmental Chamber

Flex cage for Environmental Chamber

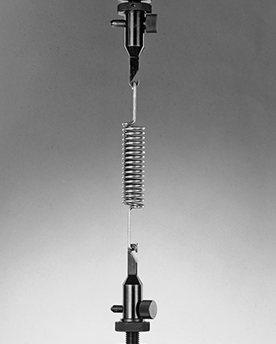

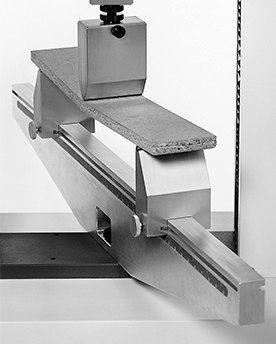

330-012 3-Point Flex Test with LVDT

330-012 3-Point Flex Test with LVDT