Testing > By Test > Compression

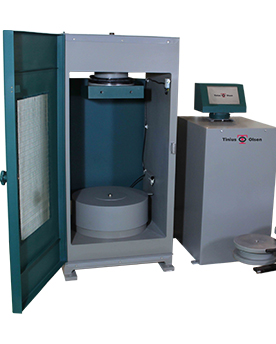

Tinius Olsen

Compression

Compression tests evaluate the static compressive strength characteristics of materials, products and components.

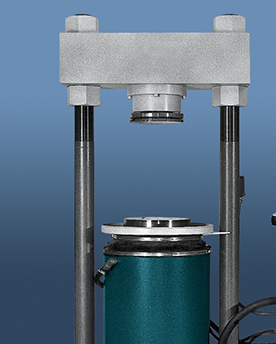

A compression test is any test in which a material experiences opposing forces that push inward on the specimen from opposite sides or are otherwise compressed, “squashed”, crushed or flattened. The test specimen is usually placed between two plates that distribute the applied load over the entire surface area of the two opposite faces of the test specimen and the plates are then pushed together by a universal testing machine to flatten the specimen. A compressed sample is usually smaller in the direction of the applied forces and expands in the direction perpendicular to the force. A compression test is essentially the opposite of the more common tension test.

To perform a compression test, a sample is loaded into a compression tester with a compression fixture and a load is applied and essentially crushed until failure.

The goal of compression testing is to determine the behavior or response of a material while it experiences a compressive load by measuring fundamental variables, eg stress, strain and deformation. Compressive strength, yield strength, ultimate strength, elastic limit, and elastic modulus among other parameters can all be determined by testing a material in compression. With an understanding of these various parameters and the values associated with a specific material, it can be determined whether a material is suitable for specific applications or if it will fail under specified stresses.

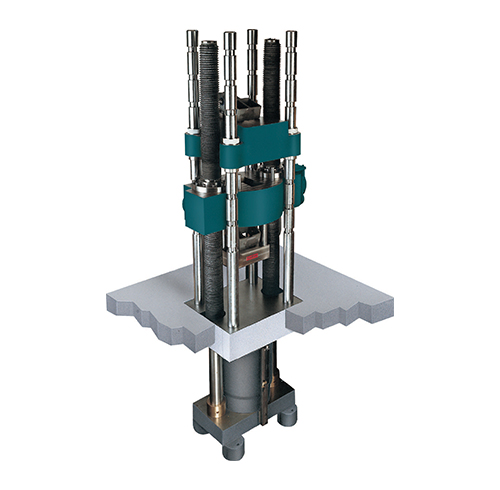

In general, a compression test for a material involves at least two opposing forces directed towards each other that are applied to opposite faces of the test specimen so that the specimen is compressed. However, there are many variations to this basic test setup that include any combination of different variables. The more common compression tests involve testing the specimen at higher and lower temperatures with a force applied to more than one axis of the specimen. Uniaxial, biaxial, triaxial, cold temperature, elevated temperature, fatigue and creep are all examples of different compression tests that can be performed on a material.

Common compression tests include:

The material subjected to a compression test typically has a compressive strength that is generally considered to be high and a tensile strength (such as a tensile test) that is considered to be of a low value. Almost all materials can experience compressive forces in one way or another depending on their application, but the most common materials include composites, concrete, wood, stone, brick, mortar, grouts, polymers, plastics, foams and metals.

Request a Proposal