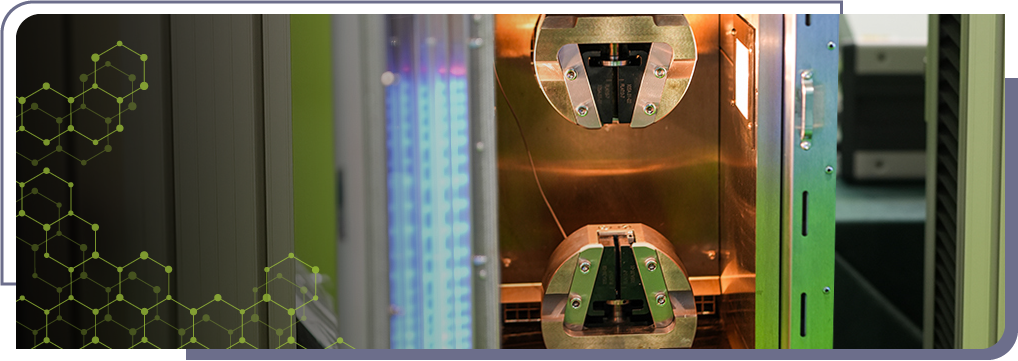

Elevated Temperature Testing Improves Manufacturing Efficiencies

You Will Learn About:

- Current elevated temperature testing

- Relevant industry standards

- Impacts to new material constructions: additive manufacturing of superalloys

Today’s manufactured products are being pushed beyond their original design limits. Modern manufacturing faces new challenges that stem from a global shift in the overall supply chain—from raw material to final product delivery—as well as operational productivity and the implications of an altered workforce dynamic. The physical properties of raw materials are under scrutiny to ensure that the correct material is selected for the right application and that the material is inherently suitable for the process at hand.

Staying competitive across all factors of the manufacturing environment is on the minds of plant engineers, product development specialists and CEOs alike.

Overview

This white paper reviews how elevated temperature testing ensures that you can confidently bring new or newly sourced materials into a production environment through proven material testing methods that validate and qualify the integrity of the materials being used.

Evaluating the behavior and performance of materials under high-temperature conditions is critical to many industries, including aerospace, energy and automotive. By studying the properties of materials when subjected to elevated temperatures, researchers can determine the maximum temperature that a product or raw material can withstand without degrading, deforming or losing its structural integrity.