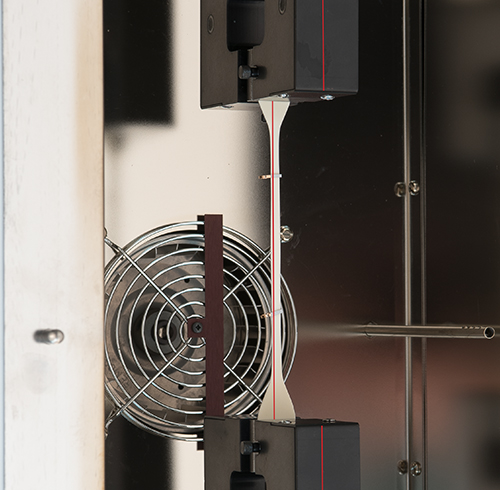

The Tinius Olsen model 500LC non-contacting extensometer is designed to measure the extension of medium to high elongation materials, typically elastomers. Since there is no contact between the extensometer and the sample, the 500LC is also ideal for measuring the elongation of fragile samples where such contact could induce a premature sample break.

The model 500LC uses a low power helium neon laser with precision optical components and a dedicated 16-bit processor. The laser projects a visible red scanning beam that is directed at two reflective targets attached to the specimen.

An additional benefit of using laser technology is its ability to scan the test specimen through the glass viewing window of an environmental test chamber. Elongation characteristics can then be evaluated from –70-300°C.

Measuring Extension

Preparation of the test specimen is quick and easy. A punch is supplied to cut narrow strips of adhesive reflective tape. The gage length is defined by attaching these two reflective strips to the sample. Any gage length can be used and this is accurately measured by the laser at the start of the test.

When force is applied to the sample, the laser scanning beam will measure the separation of the reflective gage marks at a scan rate of 320 scans per second.

Unlike other non-contacting extensometers, if the scanning beam is interrupted for any reason, elongation measurements will automatically be corrected when normal operation is resumed.

Specifications

- Range of measurement: Up to 600mm/23.6in

- Gage lengths: 10mm/0.39in to full scan

- Accuracy: 1% on 25mm gage length, BS5214 grade D

- Resolution: 0.012mm/0.000472in with filtering

- Optical scan: 320 scans per second/90 degrees

- Dimensions (HxWxD): 320 x 111 x 180mm/32 x 4.4 x 7.9in

- Weight: 7kg/15.5lb

500LC Laser Extensometer

500LC Laser Extensometer