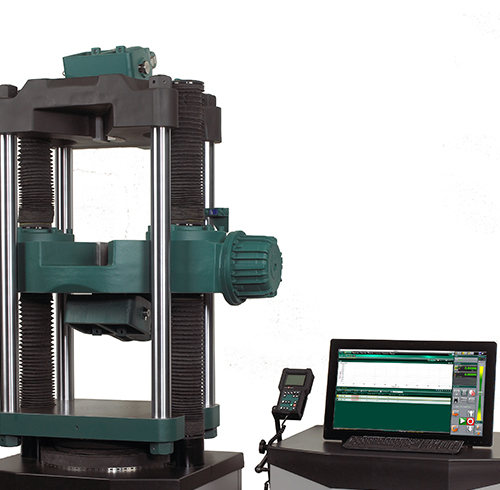

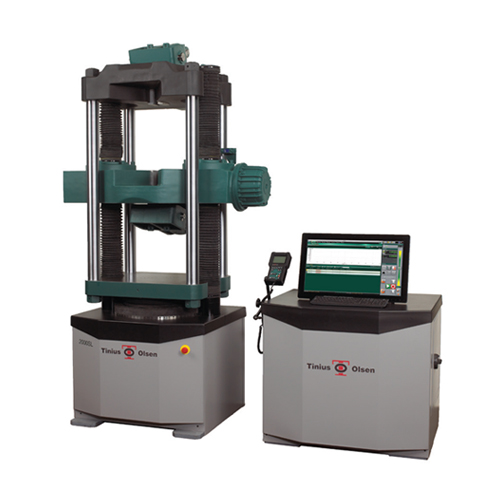

The model 1500SL is designed for tension, compression, flexure and shear strength testing on materials and assemblies. The robust design incorporates quality materials and components and ensures that our reputation for superior system performance, ease of use, and longevity is maintained.

Tinius Olsen’s hydraulic testers have long been recognized as the standard for accuracy, dependability and versatility in universal testing machines. The many thousands of testers currently in use throughout the world attest to this fact. Now more than ever, the SL series represents the highest standard in hydraulically powered universal testing machines.

Features & Benefits

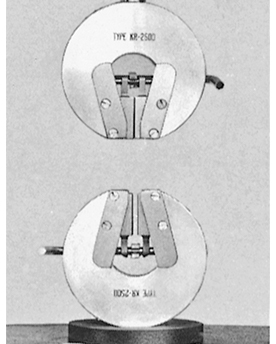

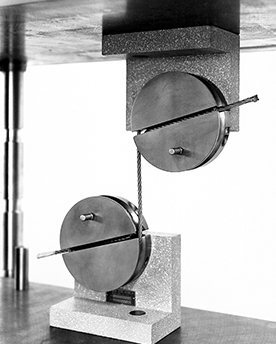

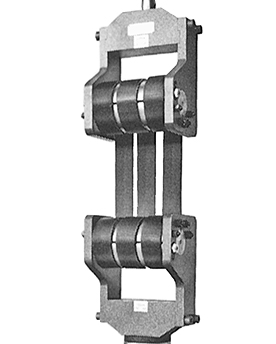

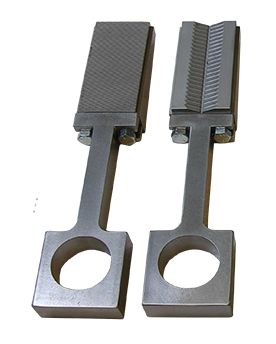

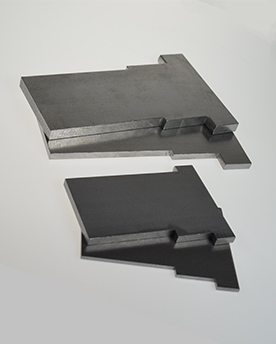

Options & Accessories

Model 150SL

Model 150SL

Model 300SL

Model 300SL

Model 600SL

Model 600SL

Model 1000SL

Model 1000SL

Model 2000SL

Model 2000SL

Model 3000SL

Model 3000SL