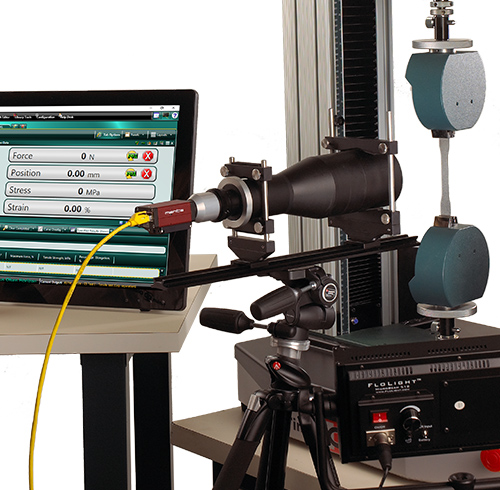

The 25ST reduced model is designed for tension, compression, flexure and shear strength testing on materials and assemblies. The frame has reduced height by 400mm as compared to standard model. The robust design that incorporates quality materials and components ensures that our reputation for superior system performance, ease of use, and longevity is maintained. A variety of loadcells are available at differing capacities that give precise applied load measurements from the smallest test specimen to ones that go to full machine capacity. Test machines become complete, powerful test systems with the addition of grips to hold the specimen, strain measurement instrumentation and Tinius Olsen’s Horizon Data Analysis software.

Features & Benefits

Applications

Most common application for this particular model includes (but not limited to):

Model 1ST

Model 1ST

Model 5ST

Model 5ST

Model 10ST

Model 10ST

Model 25ST

Model 25ST

Model 50ST

Model 50ST