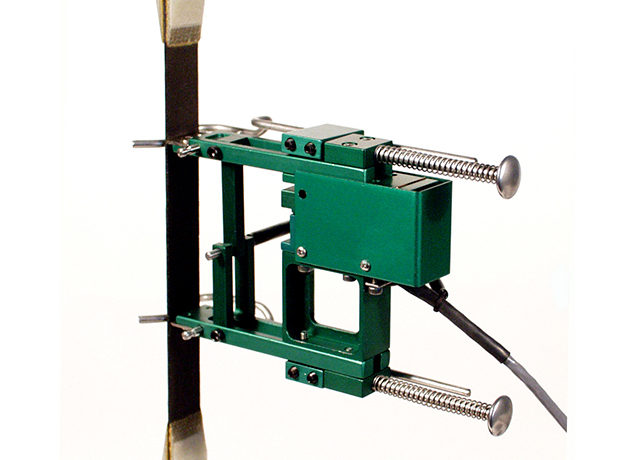

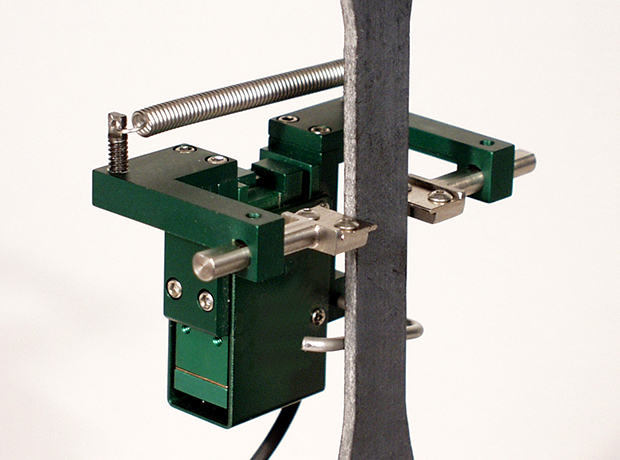

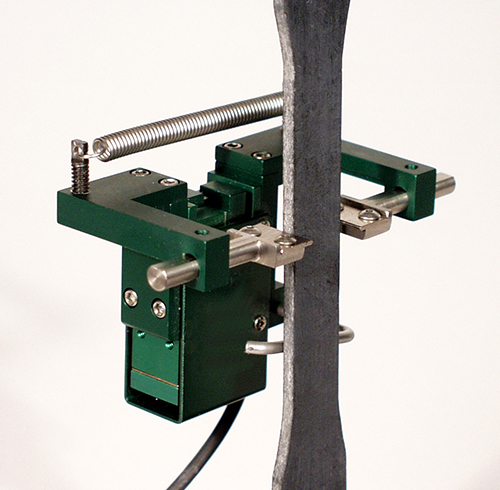

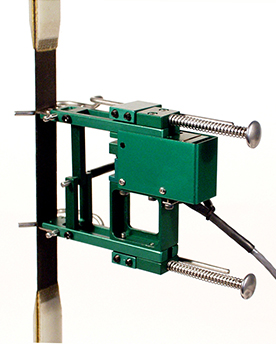

Extensometers measure strain, the change in length of a specimen divided by the original length (gage length) of the specimen, by means of knife edges that contact the sample. This series of extensometers comprises strain gage devices.

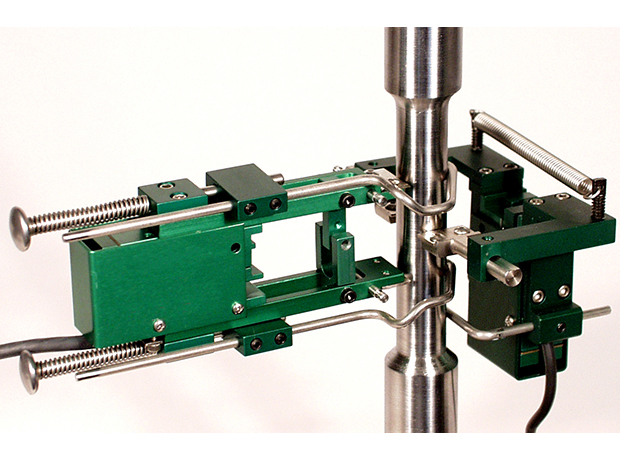

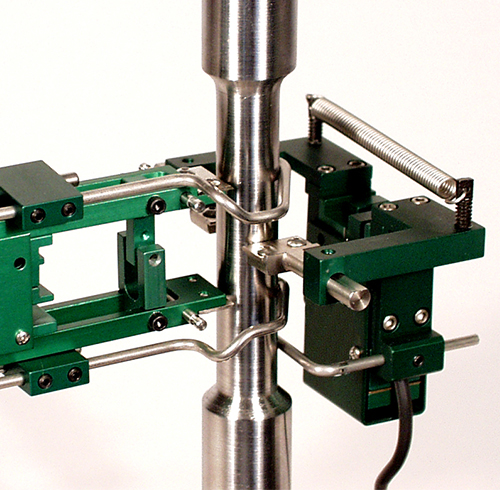

The models in this series of extensometer can be used to measure either longitudinal or transverse strain, or can be used in combination for determining ‘r’-value and Poisson’s ratio.

Features & Benefits

- Mechanical overtravel stops in both directions

- Cable stops are used for overtravel where required. Cable stops are contained fully between the arms of the extensometer and do not hang below, where they can interfere with fixturing – especially during compression testing

- Standard units meet existing ASTM class B-1 and ISO 9513, class 0,5 requirements for accuracy

- Hardened tool steel knife edges are easily replaced. A spare set comes with every extensometer

- Temperature options extend from as low as -265°C/-450°F to 200°C/400°F

- Includes high quality foam case

- Replaceable arms and spacers for ease of repair. This also allows changing the gage length for different test requirements

- Standard quick attach kit allows one-hand mounting to specimens

Specifications

SGM models – Metric units: measuring range, gage length, direction

- SGM-20%-50: 20%, 50mm, longitudinal

- SGM-20%-25: 20%, 25mm, longitudinal

- SGM-20%-80: 20%, 80mm, longitudinal

- SGM-50%-80: 50%, 80mm, longitudinal

- SGM-50%-50: 50%, 50mm, longitudinal

- SGM-100%-50: 100%, 50mm, longitudinal

- SGMT-10%-25: +/-2.5mm, 0-25mm, transverse

SG models – English units: measuring range, gage length, direction

- SG-20%-2: 20%, 2in, longitudinal

- SG-20%-1.4: 20%, 1.4in, longitudinal

- SG-20%-1: 20%, 1in, longitudinal

- SG-20%-0.5: 20%, 0.5in, longitudinal

- SG-50%-2: 50%, 2in, longitudinal

- SGT-10%-1: +/- 0.1in, 0-1in, transverse

Strain Gage Type Extensometer

Strain Gage Type Extensometer