Tinius Olsen Integral to Eco Friendly Aluminum Composite Panels Manufacturing

RMK Industries is a leading manufacturer of aluminum composite panels, supplying to more than 25 countries around the world, with its primary stronghold in the Middle Eastern, Asian and African markets. The company is trusted by internationally renowned contractors, consultants and architects, and has undertaken projects with international corporations and governmental organizations such as Shangri-la Hotels, Coca-Cola, Emaar and the Roads and Transport Authority in Dubai.

“Established more than 40 years ago, RMK Industries initially focused on the trading of architectural facade products. Over the years, we’ve transitioned into the manufacturing of high-quality architectural products and are now proud to be one of the leading manufacturers of aluminum composite panels and pre-painted aluminum coils in the Middle East,” said RMK Industries’ quality control manager, Charmaine Timario.

“Our aluminum composite panels are formulated using the finest raw materials and the latest technologies, resulting in premium quality products that match or exceed industry benchmark standards and comply with the most stringent international standards such as ASTM, NFPA , LEED by USGBC, EN and ISO.”

Aluminum composite panels are lightweight cladding panels used as external building facades and fascia to improve the aesthetic appeal and weather resistance of buildings. The flat panels consist of two thin aluminum sheets bonded to a modified mineral-filled, fire retardant core. When correctly specified, installed and officially certified to perform to code, regulations and fire safety laws, the panels provide several advantages including robust durability, light weight and high weather resistance as well as being cost effective, easy to install and low maintenance.

Sustainability at the Core

Not only focused on delivering high quality aluminum composite panels, RMK works diligently to achieve its goal to operate a sustainable business ecosystem.

“Across our entire product portfolio, we’re invested in the excellence of our products through continuous enhancement of our production processes, a strong focus on quality control and, especially, by creating a green footprint though all our manufacturing processes,” continued Charmaine.

“Achieving a sustainable ecosystem has been a core goal of ours since we got into manufacturing, and we have taken and continue to take, the necessary steps to achieve this goal. Our facilities are powered by renewable energy sources, such as solar panels and water reuse systems. We also promote the use of electric vehicles, having installed electric car charging stations in our facilities.”

“We’ve adopted the use of sustainable methods throughout our manufacturing processes, such as having a solvent recovery system in our innovatory coil coating line, ensuring the reuse of any wastage during production.”

“Our aluminum coil coating line uses chrome-free chemicals and lead-free paint, and we’re one of the first companies in the region to be equipped with a regenerative thermal oxidizer (RTO) that neutralizes more than 99% of air pollutants during the coil coating process, helping us minimize our environmental impact. Our products are 100% recyclable and are LEED-certified, contributing up to 30 points towards LEED projects.”

Materials Testing Reinforces Eco-friendly Production

“Our green initiatives will help us achieve a positive and far-reaching impact on our planet, with an estimated clean energy generation of more than 19,000 MWh and more than 8,000 tons of carbon emissions that will be avoided.”

With this and production in mind, the company ensures each product reaches all recognized international standards, with RMK operating their own in-house testing lab undertaking a wide range of tests through the entire manufacturing process.

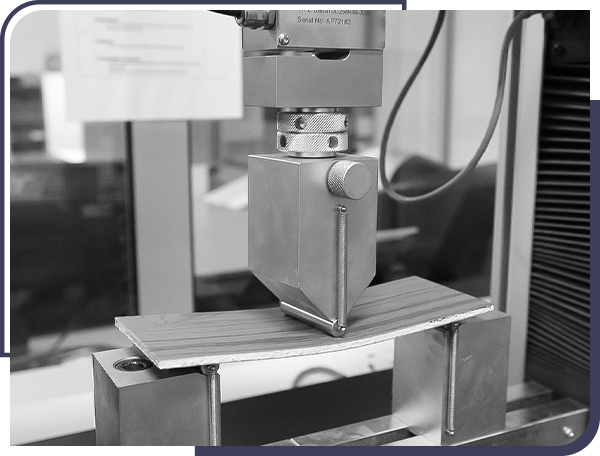

We conduct numerous mechanical property tests on our products using our Tinius Olsen 25ST, such as the 180 degree peel strength test, drum peel strength, tensile strength, punch shear strength, bending strength and various others.

After a year of working with the 25ST, it’s proved to be exceptional in meeting our material testing requirements. It helps us ensure our products are delivered to the highest of standards.”

We chose Tinius Olsen equipment due to its history, reliability and ease of use in the field of material testing. With Tinius Olsen, we can ensure our products are meeting the highest quality standards, helping us deliver the best to our customers. We are also happy with the technical support team who visits us both off and on site from time to time.”